Industrial De-Icing Systems

Winter Use Spraying Systems

Whether treating rail cars or bulk material moving on conveyors, calcium chloride has proven invaluable when cold temperatures combine with moisture to freeze processing materials.

A properly

designed system customized for your unique needs

combined with the proper strength of calcium

chloride and most efficient application rate can

virtually eliminate freeze-ups due to mother

nature.

Included in

Pollard systems are various storage

alternatives, and pumping, spraying and control

equipment. Each system must be designed

and evaluated in respect of your specific

requirements.

The movement

of bulk materials such as coal, crushed stone,

gravel and sand from rail cars and conveyors is

made much more difficult when they are frozen.

Calcium chloride, in actual use, has proven

effective as a freeze-resisting and thawing

agent.

Benefits associated with its use are:

-Improved material flow

-Decreased unloading times resulting in:

Lower labor costs

Lower hopper car

demurrage costs

Less tie-up of cars and

rail sidings

-Reduced hopper car damage by:

Minimizing car shaking

Elimination of explosives

as a means of loosening materials

-Less damage to crushing equipment:

Less production down time

Studies have

been made to determine the corrosive effect of

calcium chloride on the cars. Twenty rail

cars were assigned in dedicated service to

supply coal from Western Pennsylvania to a

production facility. Thickness readings

were taken on 12 points of each car's slope

sheets prior to beginning the tests. From

October 1979 to April 1980, approximately 1.2

imperial gallons of 32% calcium chloride

solution per ton of coal was sprayed into the

car, half on the walls and bottom prior to

loading and the remainder during loading.

A second set

of thickness readings was taken in April and no

further applications of calcium chloride were

made until October 1980 when a third set of

reading was obtained.

Tests results based on these readings are as

follows:

|

Average Corrosion/Erosion Rate in Mils |

6-Month Test Period |

Annualized |

Calcium chloride treatment |

0.8 |

1.6 |

No treatment |

4.3 |

8.6 |

As is readily apparent from these data, corrosion/erosion rates were actually higher without treatment than with treatment.

There are two reasons which may have accounted for this: greater moisture in summer cold and warm temperatures, which are factors known to increase corrosion.

Nonetheless, the conclusion is clear: calcium chloride used

according to the test conditions does not markedly contribute to hopper car corrosion rates.

There may be applications, however, that are

sensitive to corrosion. Pollard has

responded to these situations with it's

Corrosion-Reduced Calcium chloride product line.

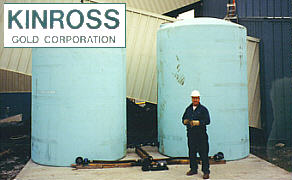

Storage System Supplied By Pollard Highway

Products

|